Shermac has been providing customised, engineered-for-purpose service vehicles to the resource sector for two decades. Customisation is critical as vehicle design must reflect the specific operational needs for the unique environment of the customer. When it comes to service vehicles, it is quite apparent that one-size definitely does not fit all.

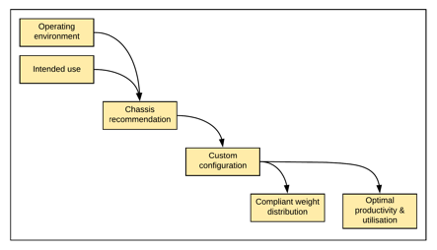

A good example of Shermac’s approach to customisation is the critical matter of weight distribution that can be summarised in the following schematic:

If the vehicle will be used on public highways, weights are limited by both the technical weight the vehicle can carry as specified by the manufacturer, and the legal restrictions as defined in the relevant road transport legislation. For instance, on the highway the allowable weight on a single front axle is seven tonnes but the vehicle’s technical weight limit might be twelve tonnes. Even though the truck is designed to carry the higher weight, it is illegal to do so on a public road.

For exclusively off-road use, weights are limited solely by the manufacturers technical weight limit, and these will typically be higher than the on-road limits. For off-road applications, an understanding of site conditions is critical to determining chassis and configuration.

The intended use of the vehicle will determine the number and type of tanks, the fluid volumes to be carried and the configuration of delivery systems. In addition, items such as roll-over protection, bull bars and tools all add weight that must be considered in load and distribution calculations.

Once all the critical operating parameters are understood, the appropriate chassis can be determined. Off-road specifications vary greatly; for example, one 8 x 4 chassis may have double the carrying capacity of another, and this might be the difference between carrying 10,000L or 15,000L of fuel and result in significant changes in vehicle uptime and productivity.

A manufacturer of standard service vehicles has a severe disadvantage when it comes to weight distribution. Mounting a standard body on any given chassis eliminates the capability to optimise design and configuration, and ultimately this impacts compliance, productivity and utilisation, and, potentially, safety.

Shermac engineers utilise technology that allows them to exactly measure vehicle load and to ensure that the load is properly distributed between the axles.

Weight distribution and compliance is verified at several stages in the Shermac customisation process. An initial weight report is submitted at quotation, another is submitted at completion of detailed design and engineering, and a final weight report is submitted pre-delivery. This is a precise art as the smallest shift can move a service vehicle from compliance into non-compliance.

In addition to weight distribution, Shermac engineers ensure that operator ergonomics, safety and productivity are all optimised ensuring the highest level of performance.

Customisation requires an understanding of the specific challenges faced by any customer, a deep-seated intellectual curiosity to look for ways to solve problems and do things better, and concept-to-delivery engineering and manufacturing capabilities.

Talk to our well-trained and knowledgeable team to find out more about our customisation process and how we can help you.

Call our team on 1300 799 943 or email [email protected] with your inquiry.